Organizations using Matterport for spatial data can now view it on the same dashboard as AWS IoT TwinMaker data with a new integration. The AWS service builds digital twins that are useful in manufacturing, construction and other heavy duty industries. Application data from AWS can also be fed back into a Matterport digital twin through the new shared dashboard.

The new integration is available now to global joint Matterport and AWS IoT TwinMaker customers.

Jump to:

- What are benefits of the new AWS IoT TwinMaker dashboard?

- How does Matterport for AWS IoT TwinMaker work?

- Why use a digital twin?

What are benefits of the new AWS IoT TwinMaker dashboard?

“Working with Matterport, we’re now able to provide customers with seamless integration of their live IoT data into detailed, spatially-accurate digital twins,” said Yasser Alsaied, vice president of IoT, AWS, in a press release.

Any Internet of Things data gathered by Matterport — which uses IoT devices such as cameras and other sensors as well as a human technician to build 3D images of real spaces — can now be smoothly integrated into AWS IoT TwinMaker. Once the digital representation of the physical place has been created and stored, AWS IoT TwinMaker can analyze data from that physical space and decide how to make allotting facility assets or setting up a production line more efficient.

“With a digital twin of our manufacturing operations, our connected field personnel can proactively enable consistently high performance of our plant assets,” Jerry Grunewald, vice president of operations transformation at Invista, told Matterport. “AWS IoT TwinMaker and Matterport digital twins provide us with a 3D visualization of our facilities for a unified view of live sensor data, equipment maintenance records and engineering design information that enable us to make effective decisions quickly.”

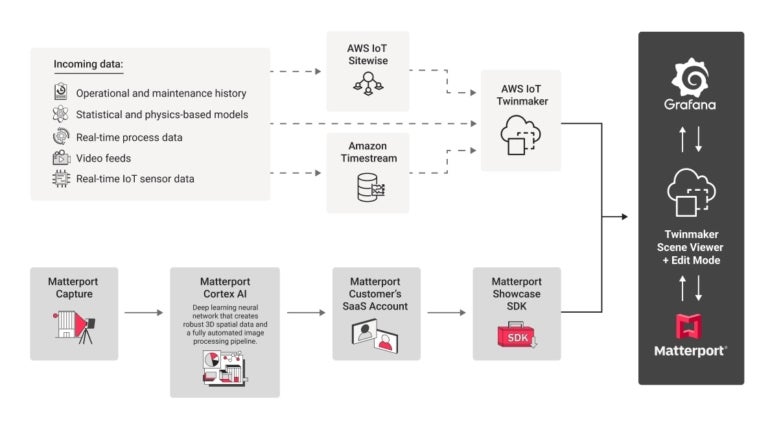

Real-time sensor and process data can be fed into the AWS IoT TwinMaker simulation (Figure A), allowing organizations to keep track of remote or complex sites more easily, Matterport said. The AWS IoT TwinMaker dashboard includes tools to analyze trends, predict problems or maintenance, provide remote training or video calls and perform hazardous work remotely. AWS IoT TwinMaker and Matterport data will be delivered to a single dashboard with the new integration.

Figure A

How does Matterport for AWS IoT TwinMaker work?

Data from the Matterport Showcase SDK is combined with AWS IoT TwinMaker in a single Matterport dashboard. This dashboard can integrate TwinMaker Scene Viewer, TwinMaker Edit Mode and Grafana (a data analytics platform) with the incoming data from Matterport. The AWS product provides the data such as operational and maintenance history, statistical or physics-based models, real-time process data or sensor data and video feeds.

Matterport has been part of the AWS ecosystem since 2021 when it became part of the cloud giant’s Partner Network as a launch partner for AWS IoT TwinMaker.

Why use a digital twin?

Twinning a digital copy of a factory floor, facility, office or outdoor location to a digital dashboard can allow organizations to improve efficiency and analyze real-time data as it comes in when done right. Digital twins have been part of the conversation around digital transformation in manufacturing for more than a decade. Digital twins remain a staple in industrial IoT and are used in network deployment.